Two important research papers in ‘Waste Management’ evaluate the impact and material flows of a ‘Quality Recycling Process’ – showing improved quality in recycled materials and end market applications. Important steps to boost recycling and circularity of flexible packaging.

Researchers at the Universities of Gent and Maastricht, together with CEFLEX consultants, stakeholders and partners have produced two academic papers for the International Journal of Waste Management, Science and Technology (Volume 153, November 2022).

The articles illustrate with metrics and material flows how flexible films can be recycled and used in end market applications applying an improved mechanical recycling process.

CEFLEX is grateful for the work of all authors, co-authors and partners who contributed to this analysis. Supporting industry with scientific insights is critical to our #MissionCircular work and progress towards a circular economy for flexible packaging.

In addition to the papers below, a public webinar entitled ‘Closing the loop on difficult to recycle plastics’ gives an accessible breakdown of key elements of the work.

An assessment of a Quality Recycling Process approach

The first, entitled ‘Quality evaluation and economic assessment of an improved mechanical recycling process for post-consumer flexible plastics’ looks at the properties and cost of recycled household flexible plastics coming out of the CEFLEX Quality Recycling Process (QRP).

It finds an improved technical performance and regranulates for use in higher value end applications – whose properties and performance in films and injection moulding is also analysed in detail.

The paper also offers an economic assessment, concluding that the investment and operational cost for the improved process is compensated by delivering more high quality recycled pellets, which can be used in more diverse applications.

Material flow analysis of post-consumer flexible plastics

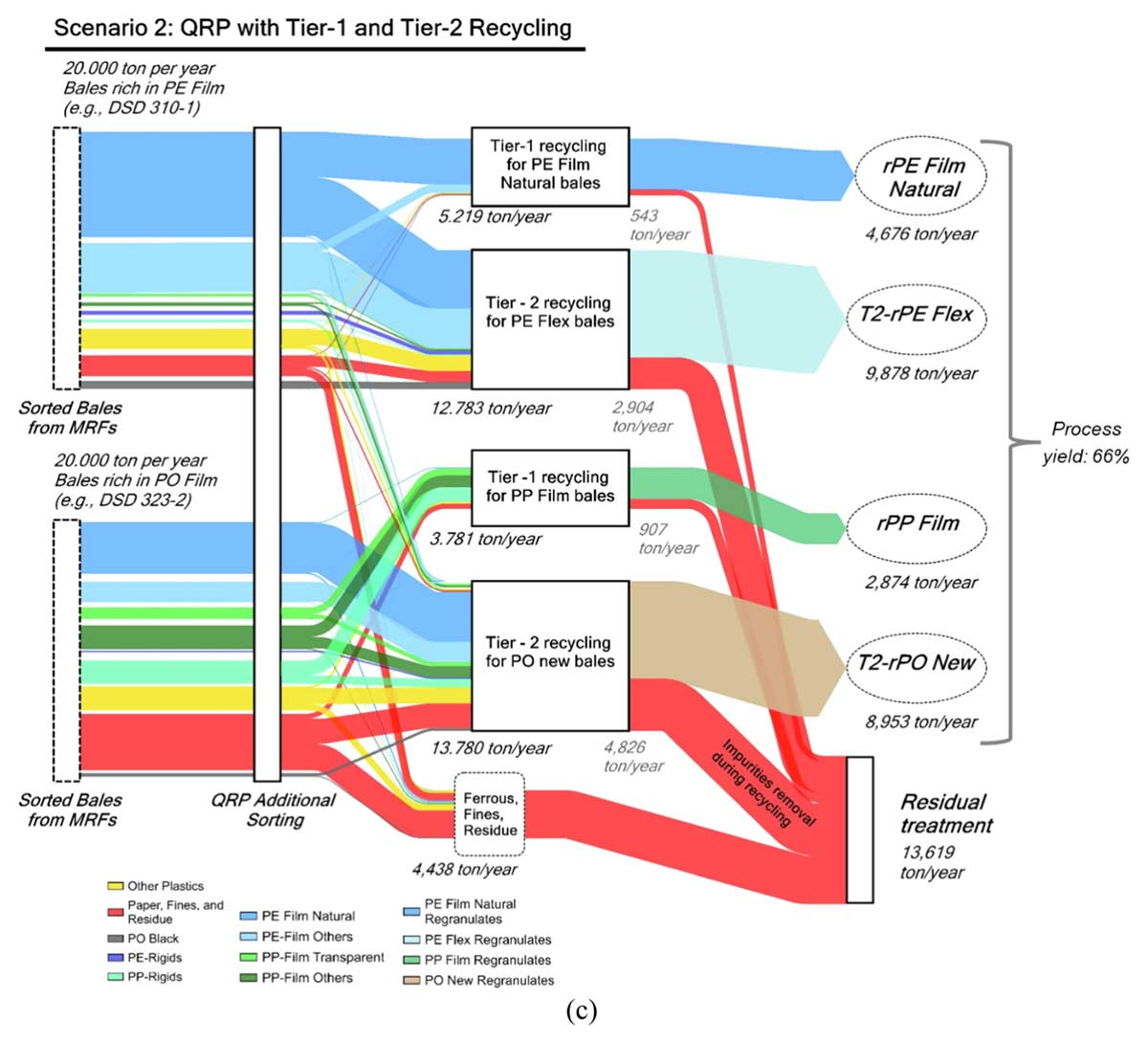

Its sister publication takes a Material Flow Analysis (MFA) approach to predict flows of post-consumer flexible plastics via mechanical recycling – an approach often used to support new plastic waste recycling systems

Titled ‘Material flow analysis and recycling performance of an improved mechanical recycling process for post-consumer flexible plastics’, it addresses the current focus on recovering rigid packaging and a picture of low recycling rates and low-quality end market applications such as garden furniture or bin bags before examining possible paths to improved quality when reprocessing post-consumer flexible packaging.

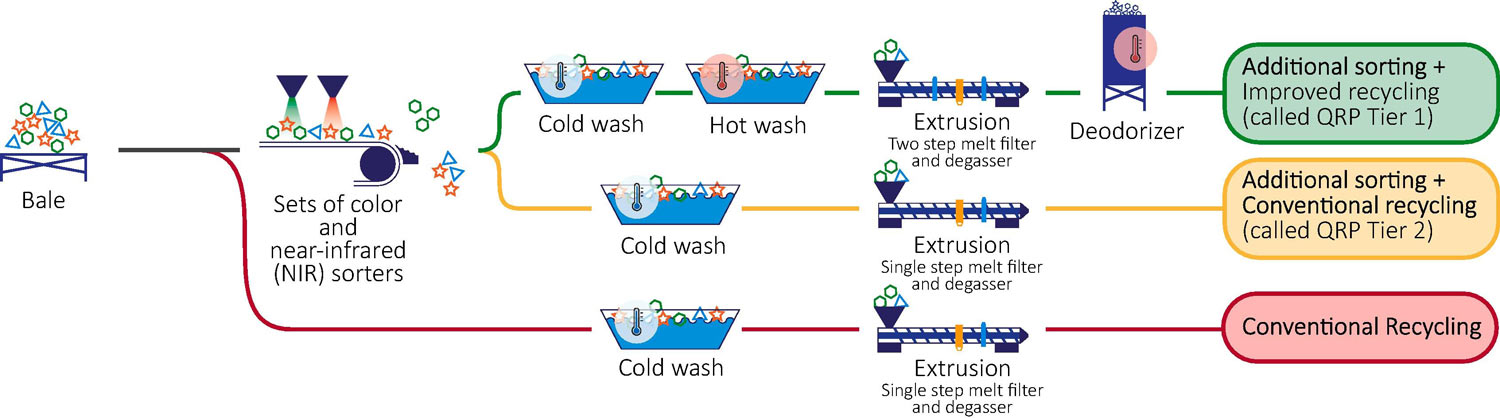

Analysis shows that the QRP process of additional sorting, hot washing with detergent, improved extrusion (with two-step filtration and degassing), and deodorization produces better quality pellets compared to conventional mechanical recycling and fulfilling a larger market for recycled plastics.

The authors assert that implementation of a Quality Recycling Process can be an important step to improving flexible packaging recycling rates and a more circular economy for the packaging format.