Sandra Beckamp, Managing Director at Institut cyclos-HTP GmbH, discusses how a unique and in-depth Near-Infrared (NIR) study showed how different designs of flexible packaging affect recognition and sortability.

What was the aim of the NIR study?

This was the first NIR study of its kind and the aim was to better understand the technology’s characteristics, behaviour and capability for detecting and classifying flexible packaging waste. The research examined numerous flexible packaging structures in a series of tests focused on detecting and classifying materials through the automated and manual examination of their NIR spectra and signal intensities.

What type of materials were examined and why?

The study gave us a huge depth of detail, thanks to around 240 samples from CEFLEX and its stakeholders. They included polyethylene (PE) films with different materials and elements added, various multi-material structures with materials such as EVOH, polyamide, metallised films and also printed films; and came from packaging suppliers and brand owners, which helped the trials reflect the diverse landscape of flexible packaging available on the market.

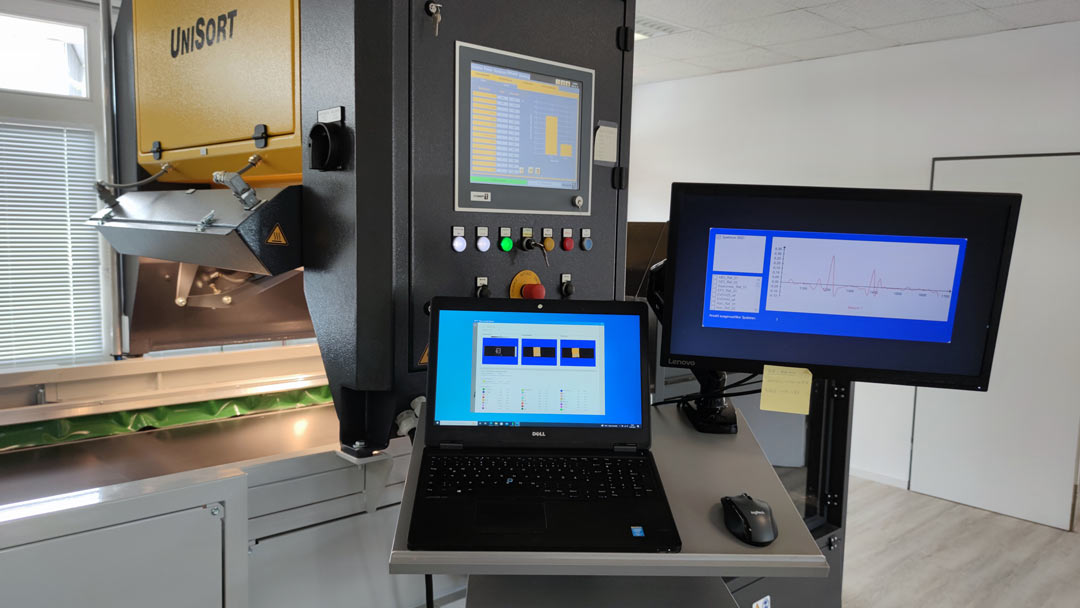

While the study anonymised the source of all the samples, CEFLEX had obtained detailed specifications about them, which supported a thorough and systematic evaluation of each sample. This enabled our collaboration with the fellow testing centres to better coordinate measurement procedures, calibration and summarisation of results. When this was combined with our industrial NIR sorting machine, which gives access to the ‘inner workings’ of the electronic data programme, we could manually review and generate raw data that provided very interesting insights, including visualisations of the materials’ spectrums (profiles).

How will these insights help the circular economy for flexible plastic packaging?

NIR sorting technology has been used in practise by the waste management and recycling industry for almost three decades, but we still lacked some fundamental understanding of how it ‘sees’ more complex structures and different types of materials, depending on layer thickness and sequence in flexible packaging. Our investigations with CEFLEX and its stakeholders not only clarified how a modern NIR camera sees the packaging, but also shows which specific design measures can be used to influence the actual sorting results of this technology in a targeted manner. In other words, our findings can be utilised in design for recycling guidelines.

How exactly did the trials improve our understanding of where NIR fits in the circular economy for flexible packaging?

Our understanding of how NIR technology works has increased in several ways as a result of the CEFLEX testing programme.

This knowledge not only improves our ability to predict how NIR sorting devices recognise specific structures, but also enhances our understanding about which structures are more efficiently recognised – this can contribute to more informed decision-making around designing packaging.

The study also identified several options to refine sorting for multi-layer multi-material structures, an improvement on what we can generally achieve today.

Were there any surprising results from the trials?

It was astonishing that almost all multi-material combinations could be specifically identified as such. In certain cases, even the concentration of the components can be determined.

Furthermore, the study showed, contrary to our previous assumptions about limited penetration depth, that NIR can penetrate significantly beyond the outer layer of most flexible packaging structures. This explains why measurement of asymmetrical structures can provide identical results from both sides.

Did the study challenge any preconceptions about NIR technology?

Indeed. We already know that carbon-based black masterbatches are problematic for NIR based sorting, but we learned this also applies to using black inks which contain carbon black, when used on large parts of the surface, such as a background colour. At the same time, testing of black print in finer patterns, such as typical for text, barcodes and line graphics could clearly be shown to not cause sorting issues.

Consult the full study and open-source results online: guidelines.ceflex.eu/testing-results

Sandra Beckamp,

Managing Director, Institut cyclos-HTP GmbH