An Interview with Klaus Wohnig, Co-founder of the DROP-IN Dissolution Recycling Initiative

Dissolution is an occasionally overlooked middle ground between mechanical and chemical recycling -but its potential is undeniable. This versatile technology is well positioned to help achieve EU legislative targets while serving key applications in personal care, industrial sectors, and beyond.

We spoke with Klaus Wohnig, Co-founder of the DROP-IN Initiative, about how dissolution can accelerate the circular economy for flexible plastics and what’s needed to scale its impact by 2030.

How does dissolution help companies comply with EU legislation and advance the circular economy for flexible packaging?

While mechanical recycling of flexible packaging is advancing, it faces well-known limitations—particularly due to colorful prints and mixed polymer compositions in post-consumer waste from curbside collection. Even with the most advanced sorting and processing, achieving high-quality recyclates new applications remains a challenge.

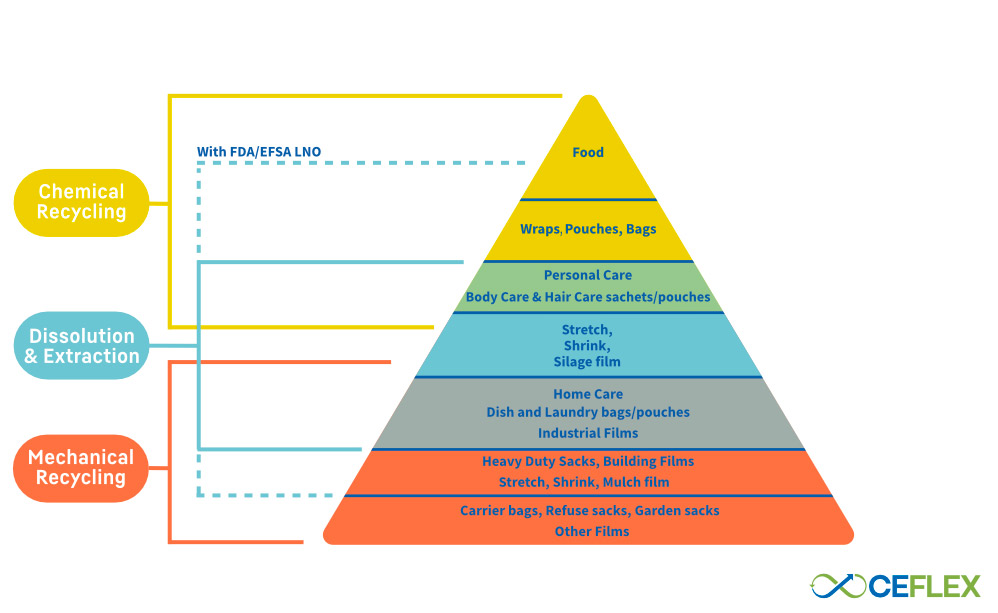

Dissolution recycling offers an innovative alternative by using a solvent-based physical process to purify and recover plastic packaging waste without breaking down polymer chains. This makes it far more energy-efficient than chemical recycling while delivering higher-quality output than mechanical recycling. Today, dissolution technologies are already capable of producing cosmetic-grade recyclates, and even food-grade applications are within reach—offering a transformative opportunity for circularity in flexible plastics.

CEFLEX assessment of mechanical, physical and chemical recycling processes aligned to illustrative end market applicatons based on quality of recycled polymers produced.

What are the key enablers for maximizing your impact in Europe by 2030?

Dissolution recycling is already present on the market and an emerging technology, but collaboration is essential to unlock its full potential. That’s why we launched the DROP-IN Dissolution Of Plastics INitiative—a platform bringing value chain players together to drive awareness and adoption.

For policymakers, dissolution presents a viable pathway to meeting ambitious recycled content targets across sectors—starting with packaging and automotive. At the same time, investor support and industry engagement are crucial to scaling the technology, expanding infrastructure, and integrating dissolution into existing recycling systems. Both of these will be key over the next three to five years in particular.

What are the biggest challenges to scaling dissolution, and how can they be overcome?

Scaling any new recycling process involves a learning curve, especially when ensuring consistent high-quality output from variable feedstocks. Success depends on strong collaboration along the value chain, from waste collection and sorting to processing and end-market applications.

Additionally, regulatory challenges must be addressed, and existing collection and sorting infrastructure will need to adapt to accommodate dissolution technology at scale. However, the key isn’t to replace existing recycling methods—it’s about integrating and intelligently combining technologies to build a comprehensive, circular system.

Discover more about the DROP-IN Initiative and dissolution recycling

Klaus Wohnig,

Co-founder of the DROP-IN Dissolution Recycling Initiative