Stakeholders across the value chain have collaborated to generate robust, independent data and improve flexible packaging design guidance. Q&A with Haulwen Nicholas, CEFLEX design testing program lead.

Tell us about the extensive mechanical recyclability testing program conducted over the last two years and what are you doing with the results?

Together with stakeholder across the value chain and partners, we set out to build transparent, comprehensive and robust data on flexible packaging sorting and mechanical recycling. Why? So, designers, brands and producers can accelerate more mechanically recyclable packaging designs with confidence. To achieve this, we brought together independent laboratories, academic advisors and subject matter experts to help develop testing methodologies for sortability and recyclability.

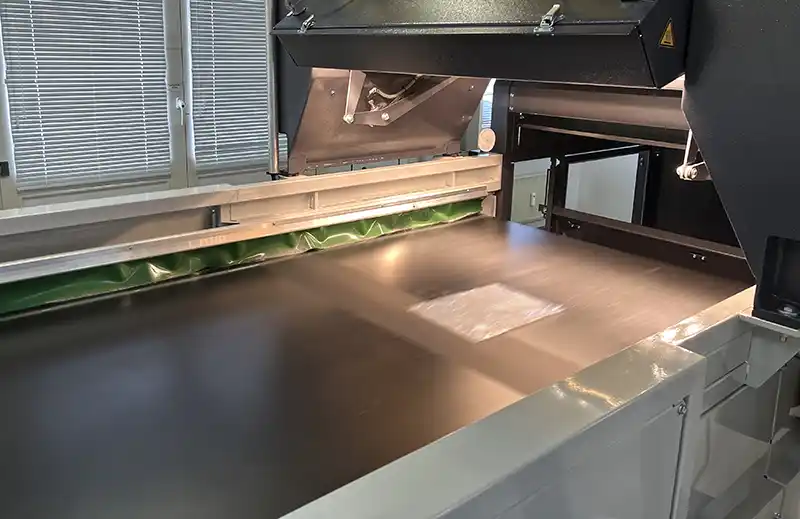

Over 600 samples were examined across different sorting methods, (NIR sorting, eddy current and metal detection sorting, size and shape sorting), and mechanical recyclability testing (both pre-screening and full testing). Our focus was on testing specific materials rather than individual packaging structures to generate a rich set of applicable insights to inform design guidance updates.

The CEFLEX team, laboratories and academic partners analysed data produced and worked with industry specialists across the value chain to determine compatibility with mechanical recycling and sorting. This collaboration was key, as no single or small group of organisations could generate this scale of samples, data and insights working alone. It would simply be too challenging, time-consuming or costly.

Everything we clarified or learnt as part of this process will be shared openly to benefit industry, standards and legislation; but importantly for us, also translate into clear, actionable design principles, updating our ‘Designing for a Circular Economy’ (D4ACE) guidelines. It’s an open access body of knowledge helping the entire value chain increase the level of collection, sorting and recycling of flexible packaging and producing higher quality recycled materials to be kept in the economy and used in a wider number of sustainable end markets.

“From a design guidance perspective, this work provides clear, evidence-based recommendations, enabling designers at brands, retailers and converters, to develop packaging that is mechanically recyclable in PE and PP flexible recycling streams”

Take us through some of the key steps shaping the ‘Phase 2’ testing program…

The testing program aimed to produce robust data to underpin design guidance. So, a first important step was examining the wealth of value chain knowledge used to develop CEFLEX’s first PE, PP and PO flexible packaging design guidelines and collectively identifying where we needed data to establish evidence or advance our understanding. These were, for example, the threshold levels at which certain barriers, inks, adhesives and other materials and elements, start to impact recyclate quality.

A second key point was developing a robust testing methodology that could produce relevant data that was clear and detailed enough that it could be independently repeated at any point. The laboratories CEFLEX collaborated with generated extensive amounts of raw data: this data has been reviewed for accuracy, consistency, patterns and cross referencing against other data points and sources from across the testing program. This process helped refine variables such as temperature, test equipment differences and control materials to enhance repeatability.

Thirdly, our stakeholders across the value chain. They have been instrumental in providing the quantity, quality and range of samples that made this testing truly possible. These contributions extended beyond material supply to shaping test parameters and reviewing data, strengthening the study’s credibility. Stakeholders also participated in hundreds of hours of meetings to define and refine the testing scope, support the data review process and help update the design guidelines.

Throughout this process, UK Research and Innovation (UKRI) has been an invaluable partner through their Smart Sustainable Plastic Packaging (SSPP) Challenge, delivered by Innovate UK. Their co-funding and collaboration was invaluable to us to taking a more comprehensive and extensive approach to this essential testing.

“The independence and robustness of the data – and its review – is intended to empower the entire value chain to make the right decisions. Guidance and standards across wider industry – including our own design guidelines – will hopefully benefit from an improved understanding”

You also included pre-screening in the testing methodology. Why was this needed and how did it improve the process?

Given the vast number of materials identified for testing, a pre-screening protocol was introduced to refine our focus. This approach allowed for initial assessments using streamlined tests, determining which materials warranted full testing. Pre-screening was particularly useful in identifying weight percentages to fully test for each material or element.

How did you approach control materials in testing and how does this differ from what others are doing?

When developing the testing methodology, we established that most other methodologies were either using a virgin one polymer control sample, or a post-consumer recyclate (PCR) sample.

However, universities and laboratories noted that these approaches could mask or alter results due to PCR variability or changes in virgin material properties by changing the virgin material.

For the testing program, we implemented an engineered base material approach to ensure consistency and to improve data robustness. This material is ‘engineered’ to be representative of a typical waste flexible packaging recycling stream composition (LLDPE, LDPE, HDPE), and provides a more realistic baseline for recyclability testing. CEFLEX used market data and industry input to establish a common engineered base material instead of relying on a virgin polymer sample.

Full reports on the engineered base material control approach and phase 2 testing methodology learnings, will first be made available to CEFLEX stakeholders, before a wider public release.

Follow our LinkedIn page to stay informed of latest developments or check guidelines.ceflex.eu.

Haulwen Nicholas,

CEFLEX design testing program lead