Interview with Andrea Cabanes Gil, CEO of Fych Technologies

Fych Technologies is a Spanish startup pioneering deinking and delamination solutions to tackle one of the biggest challenges in recycling: flexible multilayer plastics. We spoke with Andrea Cabanes Gil, CEO of Fych, to explore how their technology is driving circularity, key enablers for scaling impact by 2030, and the barriers that need to be overcome.

How does deinking with delamination help companies comply with EU legislation and advance the circular economy for flexible packaging?

Traditional recycling methods struggle with multilayer packaging, where different materials are bonded by adhesives and inks, making separation difficult and leading to contamination.

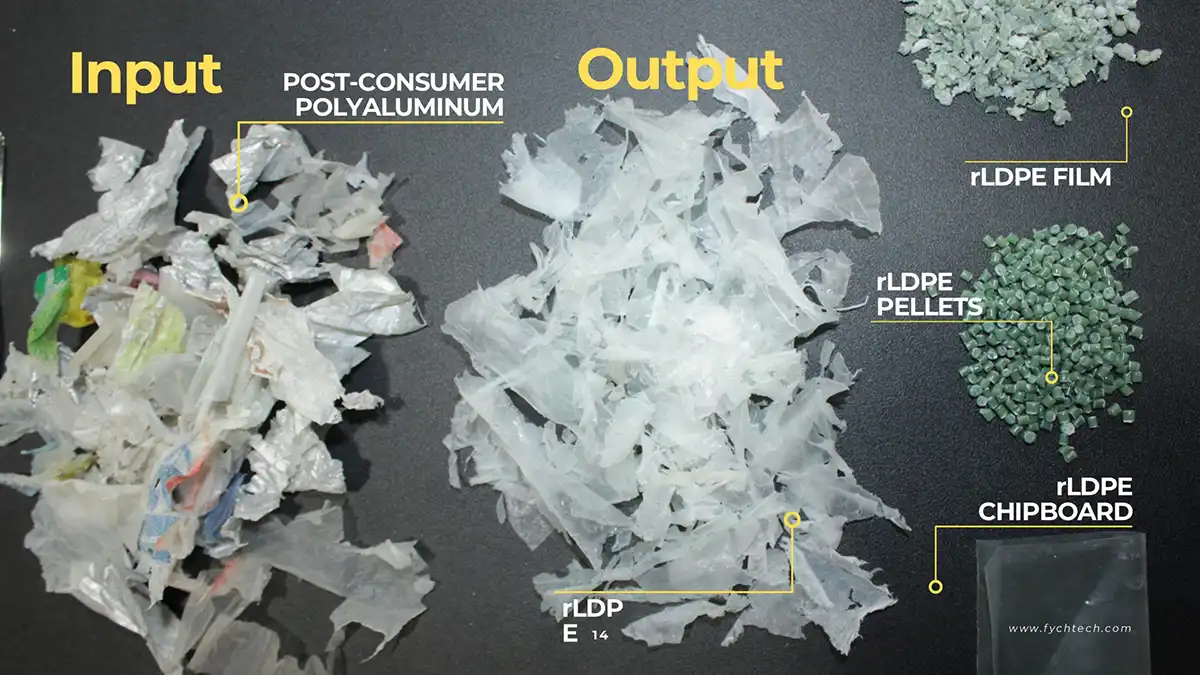

At Fych, we offer a disruptive mechanical recycling solution that enables the efficient processing of these challenging plastics—potentially even for food-contact recycled polymers.

Our process starts with a preconditioning step that creates multiple access points, allowing a water-based delaminating solution to penetrate and separate the layers. This removes adhesives and inks without hazardous organic solvents. We also integrate a decontamination step to extract organic impurities such as BPA, phthalates, and odorous volatile organic compounds (VOCs). The result? High-quality, decontaminated recycled plastics.

By enhancing recycling rates for flexible packaging, our process also helps manufacturers meet recycled content requirements set by regulations like the Packaging and Packaging Waste Regulation (PPWR), particularly targeting quality towards contact sensitive packaging applications. Moving forward, we will also assess potential of the technology to deliver even food contact quality.

What are the key enablers for maximizing your impact in Europe by 2030?

Building strong partnerships is essential for driving innovation in recycling. By collaborating with manufacturers, waste management companies, and governments, we can integrate our technology into existing recycling systems. These partnerships not only accelerate adoption but also ensure that our solutions align with industry needs and demands.

Regulation, unsurprisingly, is another key enabler, and plays a crucial role in encouraging the adoption of innovative recycling technologies. For Fych—and others working in this space—close collaboration with policymakers is essential. By engaging with decision-makers, we can help ensure advanced recycling can contribute to PPWR targets and material circularity.

At the same time, for us as a company, continuous innovation and development are fundamental. The challenges in plastic recycling are constantly evolving, and we must evolve with them. Investing in research, refining our processes, and designing new solutions are necessary steps to stay ahead. However, scaling these innovations requires financial backing. A combination of private investors, EU grants, and other funding mechanisms will be crucial for setting up demonstration plants and expanding Fych’s impact.

What are the biggest challenges or barriers to scaling your technology, and how can they be overcome?

A key barrier is regulatory approval, particularly securing European Food Safety Authority (EFSA) certification for our decontamination technology. The approval process is often slow and complex, but accelerating it is crucial for faster market entry and industry adoption.

By working closely with regulators and industry stakeholders, we can streamline the approval pathway and ensure innovative solutions like ours contribute meaningfully to achieving circularity goals.

Discover more at fychtech.com

Andrea Cabanes Gil,

CEO of Fych Technologies