What is the main concept of ValueFlex?

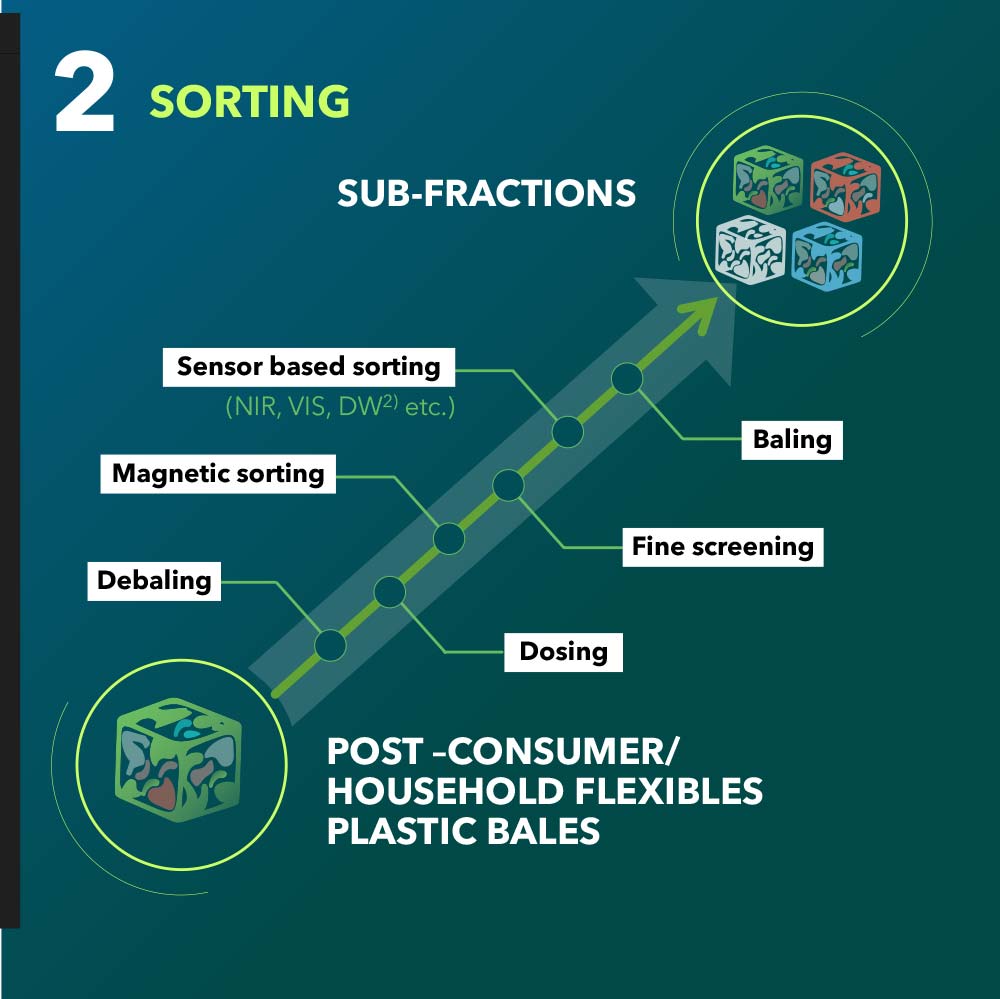

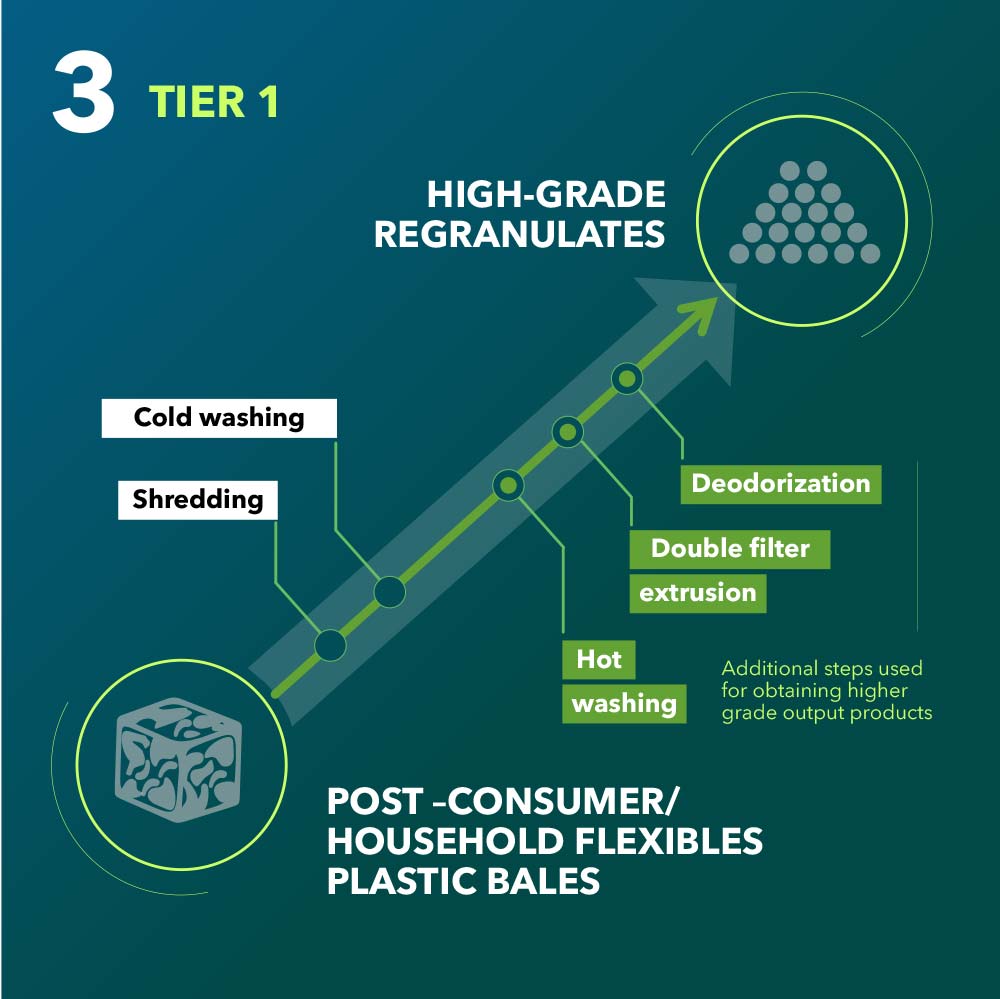

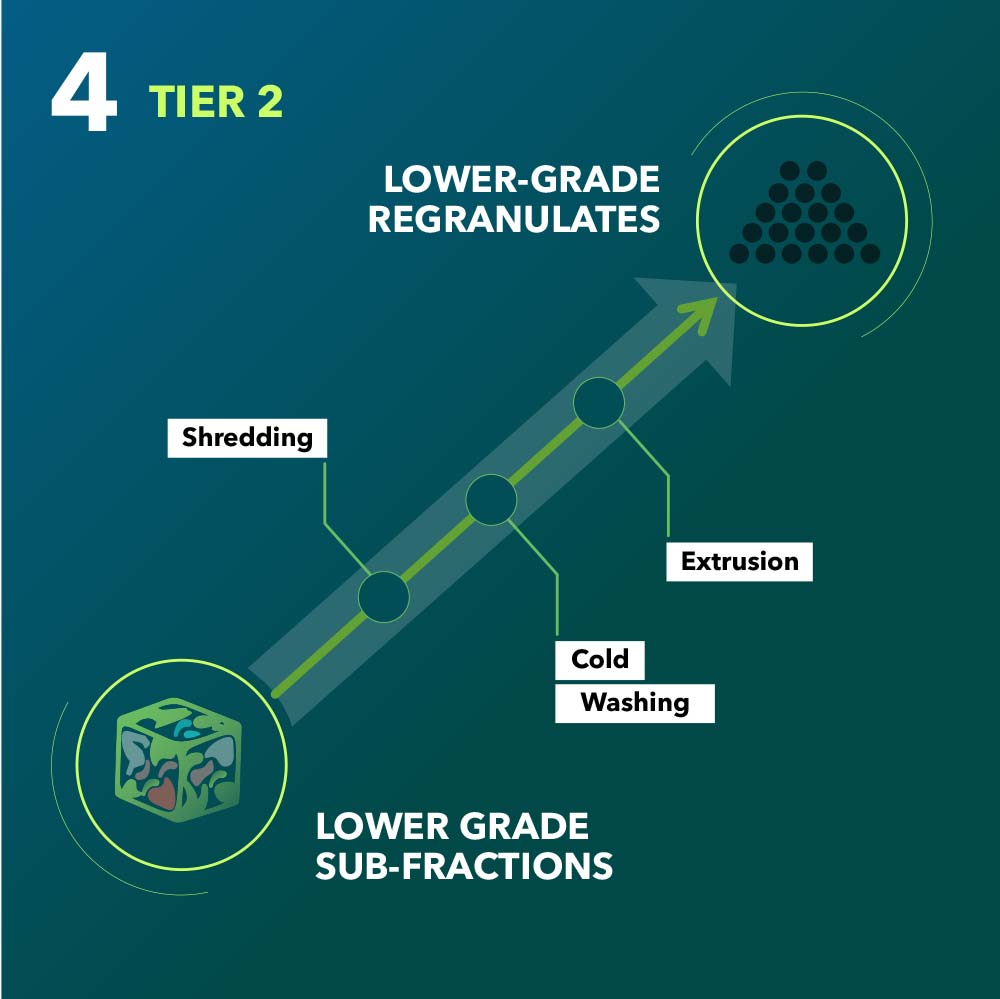

ValueFlex is a state-of-the-art recycling plant for flexible plastics from post-consumer waste. It combines existing state-of-the-art sorting, washing and extrusion technologies, to obtain high grade output products. Its flexibility and modularity ensures a high level of commercial versatility.

The feasibility of the concept – which is especially innovative as sorting and recycling is addressed in the same plant – has been demonstrated through extensive tests and trials conducted since 2018.

Moreover, demand for high-quality recycled products for film applications is expected to increase significantly in the next decade, mainly driven by regulatory targets, consumer pressure for sustainable packaging and the fast moving consumer goods (FMCG) sector’s environmental sustainability target. This means ValueFlex not only helps solve the issue of flexible plastic waste, but also addresses a market demand.

What is the main aim of the project?

ValueFlex’s unique selling proposition is that it tackles the very limited recycling of flexible plastics today in Europe, especially for household/post-consumer waste. The current rate is only 8% for polypropylene (PP) and 24% for polyethylene (PE) – almost exclusively obtained from industrial and commercial packaging such as wrapping around boxes collected in warehouses. We want to increase recycling rates to 30% for PP and to more than 50% for PE.

This will help contribute to the overall plastics recycling targets of 50% by 2025 and 55% by 2030 in the European Union (EU) packaging and packaging waste directive with recycling rates already over 50% for PET.

We aim to design the first plant in such a modular way that it can accommodate further technological innovation, especially for sorting, where various technologies can contribute to more granular sorting of waste inputs in future.

We want to prove the concept at an industrial scale in Europe and then roll it out globally. Other important aims are proving the commercial viability of mechanical recycling at scale for flexible plastics at the same time as maximising film-to-film processing.

The project also wants to enable food-grade recycling of flexible plastic waste sourced from post-consumer waste. This would be a ground-breaking achievement and provide tremendous opportunities in this field.

ValueFlex further has a unique pull of technical expertise from the Circular Economy for Flexible Packaging (CEFLEX) initiative and the Alliance to End Plastic Waste (AEPW). They bring together, as strategic partners, top international companies from all parts of the value chain. This gives great potential to raise awareness of recycling flexible plastics and to boost recycling. And by sharing valuable know-how and findings with the industry, ValueFlex is encouraging development of similar projects worldwide.

What is the current timeline for ValueFlex?

The launch of a commercial scale demonstration plant is planned for Q1 2025, and the plant will be in Europe: with options including France, Italy, the Netherlands and Eastern Europe.

With 50,000 tonnes in the input process, you need a big market and enough flexible plastics made available.

Bidders also need to be a group formed from a converter and a recycler and someone who guarantees the feedstock, either a waste collector or a producer responsibility organisation (PRO). It is easier if countries have just one PRO and take control over the whole country like France (CITEO), Italy (CONAI) and the Netherlands (Afvalvonds Verpakkingen).

What will be the next steps?

The expression of interest and tendering phases began in November 2022. This will lead to the selection of operating partners and investors who will then decide on the exact plant location. For example brownfield (existing) sites are preferable to greenfield sites as the permits are already there with makes the project quicker and cheaper. The budget range is between EUR50 and EUR80 million to build the plant ready for operation.

Plant design will start in summer 2023, with permitting and construction of the plant planned to begin in autumn 2023 and take one year to 18 months.

What is the impact and the key benefits of the ValueFlex approach for the environment, consumers and industry?

ValueFlex will increase the flexible plastic packaging recycling rate from household waste, hitherto seen as non-recyclable. Recycling at scale with high-end applications for plant outputs with feedstock from post-consumer waste currently does not exist.

The plant will help solve a significant environmental issue – climate change – as it has a low carbon footprint compared to existing alternatives. Moreover, flexible packaging – mainly food packaging and bags – instead of being seen on the streets, forests and in the water will be recycled into more bags.

Consumers increasingly want sustainable, recyclable packaging and packaging made out of recycled content and will even pay a price premium for this. ValueFlex addresses these expectations and in the bigger picture tackles the overall littering and landfilling rates.

ValueFlex also aims to be an open source of information and pave the way for further developments in the sector globally. CEFLEX will contribute expertise and finance for the demonstration plant. In the next three to four years, the knowledge, business case, economics and design elements will be made publicly available for other companies, so they can also build plants in future.

Dragos Popa,

Principal, Roland Berger