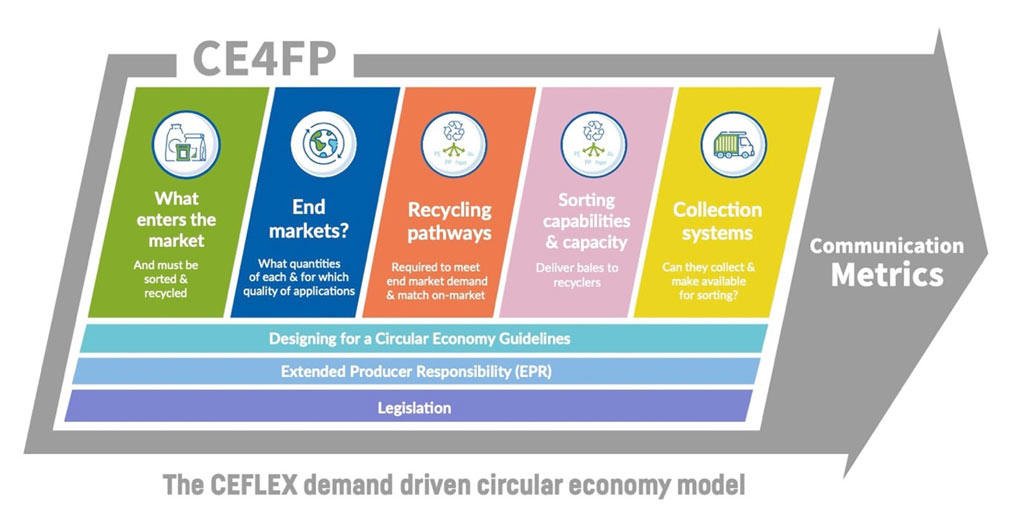

For the circular economy to be truly sustainable, we need it to be demand-driven. Powered by a pull for recycled content in clearly identified existing and significant new end markets for these materials as they re-enter the economy.

Based on a clear understanding of the potential to use recycled materials and in which markets, CEFLEX has worked backwards along the value chain to further clarify the required scale of mechanical and chemical recycling, sorting capacities and infrastructure – plus the transformation in collection needed to fuel it.

Drawing on this work, CEFLEX supports the Ellen MacArthur Foundation’s recent call for urgent investment of at least €2 billion to achieve a 4 x increase in recycling capacity by 2025 and urges all value chain players to support these investments in the needed capacities. We also call on all EU Member States to ensure that the obligation to separately collect waste is implemented.

CEFLEX’s work indicates achieving this fourfold increase includes doubling mechanical recycling capacity of PE film to 3 Mtpa, developing a recycling stream for PP film with more than twice today’s capacity for PP and PO; along with an additional equivalent 3Mtpa capacity in chemical recycling.

Giving the clarity and confidence to act

As a project, CEFLEX is working to bring scale, understanding and confidence to stimulate the necessary transformation with industrial pilots and end market insights.

These include semi-industrial trials of a Quality Recycling Process which have shown improved quality and higher value end market applications for recycled flexible packaging materials, supported by financial analysis and an emerging business case to support investment in infrastructure.

Value chain alignment is also essential to accelerate and scale progress, and a CEFLEX position paper on Recycling Capabilities for Flexible Packaging in a Circular Economy signifies the emerging clarity from industry on a way forward. It outlines how all recycling technologies are required to ensure material is retained in the economy to be used by end markets and applications.

Implementation phase for the CEFLEX circular economy vision accelerates

Industry and legislators are now at ‘the business end’ of exactly how the circular economy becomes reality at scale. A priority now for CEFLEX is working to provide knowledge and other resources to support EPR systems, infrastructure pilots, metrics and end market developments. These include:

- A next generation demonstrator to build confidence and accelerate investment

The Quality Recycling Process from CEFLEX and its stakeholders aims to tackle key issues raised by EMF by developing a modular and responsive sorting and recycling approach. It enables a much greater percentage of flexible packaging to be returned to the economy – and in the quantities and the qualities needed to meet the requirements of new end markets and a commercial QRP waste processing plant is planned for next year.

- Identifying new and growing existing markets for recycled materials

To make the fundamental switch from a linear to the circular economy, we need end market pull for recycled plastics and to make them financially competitive against the virgin equivalent.

CEFLEX has identified end markets for an additional potential 1 to 2 million tonnes per annum of post-consumer mechanical recycled materials from flexible packaging. This additional volume of post-consumer recyclate would be a significant contribution from the flexible film and packaging sector towards reaching the Circular Plastics Alliance (CPA) recycling targets and significantly increasing circularity.

A series of factsheets outlining the specific opportunities for recycled content and their applications in various market segments are in production to extend these insights and help develop new business opportunities in the circular economy.