CEFLEX News & Events

Interview: Jesús MAZA LISA, Packaging Materials Development Manager – Flexibles, Danone

As industrial trials of a CEFLEX stakeholder developed Quality Recycling Process begin, we spoke to Jesús Maza Lisa, Packaging Materials Development Manager – Flexibles at Danone to find out more about what it means for brand owners, recyclability and ‘closing the...

Interview: Gareth Callan, PepsiCo Sustainability Packaging Manager, R&D

As industrial trials of a CEFLEX stakeholder developed Quality Recycling Process begin, we spoke to Gareth Callan, PepsiCo Sustainability Packaging Manager, R&D to find out more about what it means for brand owners, recyclability and ‘closing the loop’ on flexible...

Accelerating a circular economy for flexible packaging

Two new additions to the CEFLEX team bring expertise and insights to support stakeholder collaboration and ‘Mission Circular’ goals.

Self-adhesive label companies launch a broad-based industry recycling initiative

CELAB – Toward a Circular Economy for Labels – collaboration of the whole self-adhesive label value chain aims to collect and recycle their used release liner and matrix material.

Developing Innovation at Speed and Scale

Facilitating techology is a vital element of delivering the circular economy and one of the ‘5 steps’ in our roadmap. The CEFLEX innovation pipeline process is to scout, engage and support some of the most promising.

Extended Producer Responsibility (EPR) – the what, why and how!

Extended Producer Responsibility (EPR) plays a pivotal role in funding, coordinating and facilitating the recycling of consumer flexible and all packaging. CEFLEX and its stakeholders have been working to ensure EPR mechanisms are able to drive cost-effective...

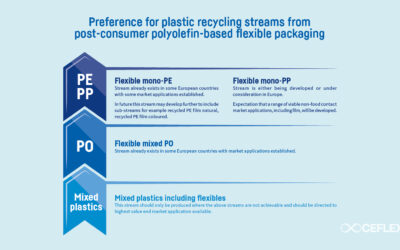

First Position Paper points to collaborative effort towards a circular economy

CEFLEX recommends use of recyclable mono-materials for flexible packaging As part of its ‘Issue Alignment’ process, CEFLEX stakeholders are working with Swiss University ETH to collect and assess topics which are essential to realising a circular economy for flexible...

Adding scale and scope to digital watermarks for smart recycling

‘Holy Grail 2.0’ technology to better sort post-consumer waste recently took a major step forward towards mass adoption thanks to a AIM brand-led consortium of 85 companies and organisations – including CEFLEX and many of its stakeholders. “We need to scale and...

European flexible packaging industry agrees unified Sustainability Vision

Flexible Packaging Europe (FPE) recently launched their vision for flexible packaging in a sustainable Europe. The vision reinforces the industry’s commitment to a common position on the circular economy. The Sustainability Vision is targeted at both the...

Is consumer flexible packaging recyclable?

A recent blog post from CEFLEX projet coordinator, Graham Houlder argues 'It’s complicated, controversial and surprisingly simple all at the same time' but at the heart of it is three conditions for success... "The good news is that we now understand what the CE4FP...

Brand owners and retailers elect new CEFLEX Steering Committee member

Feliks Bezati, Global Sustainable Packaging Manager at Mars was nominated as representative of the ‘Brand Owners and Retailers’ segment of the value chain within CEFLEX and will take a seat on the CEFLEX Board and Steering Committee. He takes over from Sokhna Gueye,...

New design guidelines set to help deliver a circular economy for flexible packaging

PRESS RELEASE A comprehensive set of guidelines to help the flexible packaging value chain design recyclable consumer packaging solutions and accelerate a circular economy was officially launched today (09.07.20). Produced by the Circular Economy for Flexible...

Explore, share and apply the ‘Designing for a Circular Economy’ guidelines

The 'Designing for a Circular Economy' (D4ACE) guidelines now have a dedicated website to better explore, share and apply their resources across your organisations. Consult www.ceflex.eu/guidelines Discover the key design principals & choices Introduction to...

Design and collaboration: key ingredients of a Circular Economy

Interview with Liz Morrish, CEFLEX Workstream Consultant and Designing for a Circular Economy Guidelines lead What do the ‘Designing for a Circular Economy’ guidelines (D4ACE) provide for the flexible packaging industry? The D4ACE guidelines...

The role of design in a circular economy

As the 'Designing for a Circular Economy' guidelines begin to launch, Graham Houlder, CEFLEX project coordinator, talks about the role of design and its effect across the value chain. Why is it so important to achieve a circular economy for flexible packaging –...

Creating a paradigmatic shift – flexible packaging in a circular economy

Incremental innovation in silos not enough, says Dr. Catharina Bening, of the Group for Sustainability and Technology (SusTec) at Swiss university ETH Zurich – working with CEFLEX to increase common understanding and action towards a circular economy for flexible...