CEFLEX News & Events

A new benchmark in open data and understanding to design more circular flexible packaging – Dr Karlheinz Hausmann, Dow Europe

CEFLEX’s new testing programme to update its Design for a Circular Economy guidelines (D4ACE) can provide the flexible packaging sector the data it needs to design more sustainable packaging, according to Dr Karlheinz Hausmann who develops packaging for Dow Europe.

Stronger data builds confidence in circular flexible packaging – Q&A with Prof. Kim Ragaert from Maastricht University

How can flexible packaging be better designed for circular sorting and recycling? A new testing programme is generating a wealth of independent data to accelerate the design of circular flexible packaging, according to reviewer Professor Kim Ragaert, chair of Circular Plastics at Maastricht University in the Netherlands.

Flexible packaging containing aluminium foil added to CEFLEX design guidelines remit

CEFLEX in collaboration with Flexible Packaging Europe, the European Aluminium Foil Association and other key actors are working on ‘Designing for a Circular Economy’ guidelines for flexible packaging containing aluminium foil.

Plugging recycling data gaps in flexible packaging design – Q&A with Dr Bronagh Millar from Queens University Belfast

Many designers lack the information to ensure their flexible packaging can be recycled, but a new testing program is working to plug these knowledge gaps by independently verifying the ideal mix of materials, according to Dr Bronagh Millar, from the Polymer Processing Research Centre at Queen’s University Belfast in Northern Ireland.

CEFLEX ‘Quality Recycling Process’

Task team develop mono-material duplex laminated pouches using PP recyclates

What can and cannot be sorted for recycling? Major testing programme advances

A comprehensive experimental study of how more than 200 different flexible packaging samples behave in the most common optical sorting process generated concrete insights and will drive design recommendations for the flexible packaging sector – with CEFLEX stakeholders getting first access to insights from September 2022

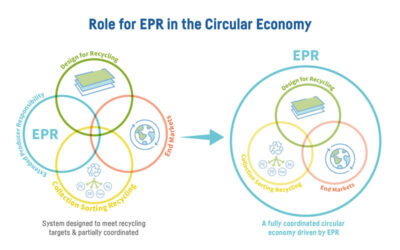

CEFLEX launches EPR ‘Criteria for Circularity’ in flexible packaging

A constructive and practical check list for EPR schemes and stakeholders to help make packaging waste materials circular come at a critical moment, as EPR schemes look to meet higher recycling targets and align with other legislation

Positive signs of momentum and urgency to make the circular economy a reality for flexible packaging materials

2022 is advancing with noteworthy consensus from a wide range of organisations from all parts of the value chain about the need to re-engage with and accelerate the urgent business of making packaging environmentally and economically sustainable says Graham Houlder.

Cascading Recycling Technologies for a Circular Economy

How can mechanical & chemical recycling work together in practice to achieve full material circularity? We speak to Stephan Roest of Borealis about navigating the circular cascade and more…

Implementation phase for CEFLEX circular economy vision accelerates

Additional knowledge and support to guide developments in EPR, infrastructure pilots, metrics and end markets as Louis Lindenberg and Michael Scriba join the #MissionCircular team

How can mechanical and chemical recycling work together in practice?

Creating, planning and investing in meaningful synergies starts today… #MissionCircular spoke with Clemens Kitzberger and Klaus Lederer of EREMA Group to help unpack how they work together to boost circularity.

Investment in infrastructure – an urgent requirement

For the circular economy to be truly sustainable, we need it to be demand-driven. Powered by a pull for recycled content in clearly identified existing and significant new end markets for these materials as they re-enter the economy.

Expanding collection of flexibles for recycling

Collecting flexible packaging is key for a circular economy because it sources the feedstock for future sustainable products. Minor adjustments to Europe’s existing waste systems can help send more of these soft plastics where they need to go.

Radically improving flexible packaging design

A core activity of the flexible packaging value chain to transform how packaging is designed is aligning and accelerating progress.

Flexible packaging – the urgent actions needed to deliver circular economy solutions

CEFLEX welcomes Ellen MacArthur Foundation call for urgent innovation and investment in flexible packaging.

Complementary Recycling Technologies for a Circular Economy

How can mechanical and chemical recycling work together in practice to achieve full material circularity? Dana Mosora helps us understand what it means in practice and the road ahead…